How Assisted Reality is Transforming Hands-On Work

How Glass fits into the flow of work to save time and money

Last year, I visited the bottling plants of a leading soft-drink company. As I walked around the massive floor with sounds echoing from all directions, I was left with an impression of a well-orchestrated industry working on a grand scale. After spending more time with the team I learned one of the biggest challenges they face is downtime caused by problems with the unique machines and pieces of equipment. These parts come from many different places and manufacturers from all over the global, and require unique expertise. What if, instead of flying in a representative from the manufacturer, the company used Assisted Reality to help their own workers to fix the problems on-site?

These are the kinds of challenges the Glass team is working to solve, so companies struggle less to get specialized knowledge from centralized repositories out into the field. Bringing Assisted Reality to wearable technology in general, including smart glasses like Glass, means the technology is able to understand a user’s specific needs and layer in relevant information. Then, workers can apply this insight — whether aided by a particular tool, a diagram, or a procedure — to improve the efficiency and effectiveness of their work.

In the case of the soft-drink company, we helped the director of operations see the potential of Assisted Reality to improve uptime by providing remote assistance via hands-free video chat between the bottling-machine specialist in Germany and an on-site worker to quickly assess, triage, and fix the issue. Assisted Reality empowers “hands-on” employees to see the results of improved quality, increased accuracy, and faster time to completion. These benefits are becoming a reality across industries.

Getting the job done faster and more affordably

For workers and professionals in fields such as manufacturing, logistics, field services, and healthcare where there is often a need to reference lots of content that they might otherwise forget, Assisted Reality is providing very real and appreciable returns on investment.

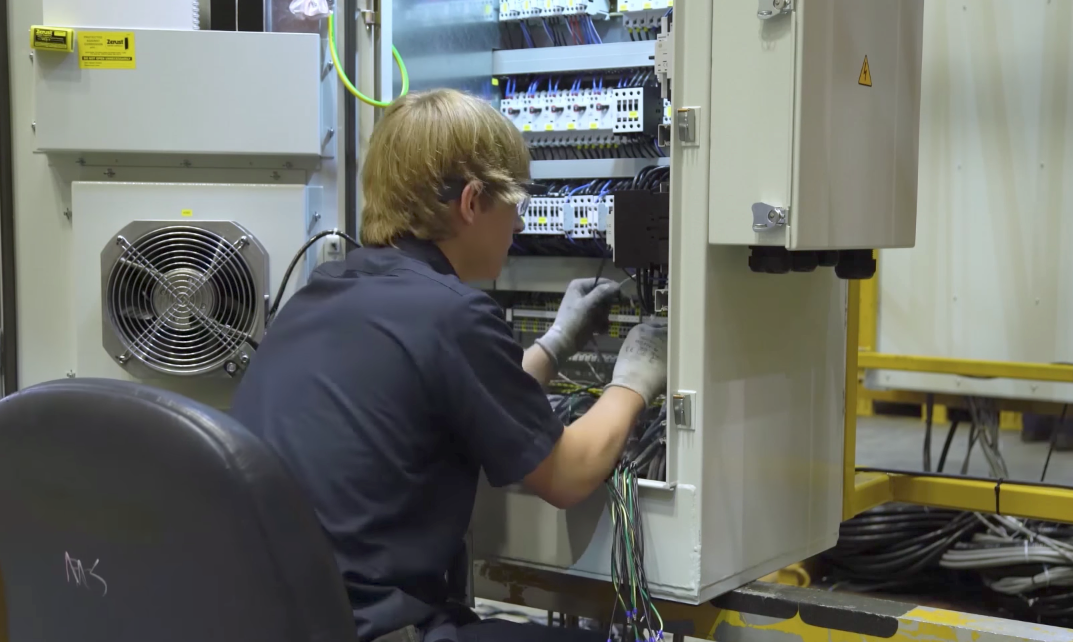

A mechanic at GE Aviation using Glass to assemble a wind turbine control module

- Mechanics at GE Aviation who are responsible for the complex assembly and repair of airplane engines are now using Assisted Reality through Glass to view instructions with videos, animations, and images right in their line of sight so they don’t have to stop work to check their binders or computer to know what to do next. Since they started using Glass, GE Aviation estimates they have not only reduced errors at key points in the assembly and overhaul of engines, but also they have improved their mechanics’ efficiency by between 8–12 percent

- Employees at AGCO, an agriculture machinery manufacturing company, are using Assisted Reality to reduce the amount of time spent transitioning in and out of their workflow to access checklists, view instruction manuals, and send photos from tablets or laptops while they’re assembling machinery. Using Assisted Reality with Glass, AGCO has reduced their machinery production time by 25 percent and inspection times by 30 percent.

- In healthcare, the quality of care is important to providers and patients alike, and physicians with Dignity Health have been using Glass during patient consultations to provide a better experience. Thanks to Assisted Reality, they’re able to use software that accurately transcribes their spoken notes. Ultimately, they’ve reduced the amount of time spent on administrative tasks, including transcribing and typing up patient notes, from 33 percent of the day to less than 10 percent. This change has enabled them to double the amount of time they interact with patients.

As an industry, makers of wearable technology are just starting to scratch the surface — pun a little bit intended — with Assisted Reality. As the Glass team continues to build solutions for hands-on workers across industries, we’re listening to them and working with software partners to further advance the potential of these devices in the enterprise. From agriculture to health care to manufacturing and beyond, there are countless possibilities for how Glass can help people work better, smarter, faster, and safer.