The Moonshot Factory Operating Manual

X's approach to inventing and launching new moonshot technologies

Ever since we started as Google[x] in 2010, X has had a single mission: to invent and launch “moonshot” technologies that we hope could someday make the world a radically better place. We developed a simple blueprint to help us find ideas that could deliver 10x impact, not just incremental improvement over the status quo: an X project must solve a problem that affects millions or billions of people; it has to have an audacious, sci-fi sounding technology; and there has to be at least a glimmer of hope that it’s actually achievable in the next 5–10 years.

Over the years, we’ve gotten better at finding and developing moonshots that satisfy these criteria, and we’ve learned a lot along the way. What makes this really difficult is that innovation is a delicate thing. You can’t over-process it; you have to respect weird creativity and serendipitous discovery. But if someday you’re going to harvest the fruits of that innovation in the form of revenue and profits, you need to find just the right amount of structure. That’s why we’re trying to build X into a “moonshot factory”.

At X, we’re trying to do much more than just research dazzling new tools and scientific approaches. We’re trying to create the processes and culture that will help us systematize innovation. (We’re not the first to try this, of course; we can trace our inspiration at least as far back as Thomas Edison.) We hope to find repeatable methods for delivering real impact to the world, by developing technology products that provide the foundations of large, sustainable new businesses.

What I’ll share today are some of the factory processes we’ve developed over the years to keep ourselves in the sweet spot between high-risk/idealistic (where most research lives), and safe-bet/pragmatic (where most big companies live).

Responsibly irresponsible

We embrace failure as a powerful tool for learning and, counter-intuitively, making progress; this is one of our most important values. Now, you might be a bit concerned about someone sitting in the CEO chair telling you they’re setting out to fail most of the time. But to make progress toward any audacious idea, you have to make mistakes — you have to seek out frequent, messy, instructive failure that shows you what to do (or not do) next. You can read more in my SXSW talk here and my TED talk here about how this philosophy shapes X’s technology development, and in this post I’ll explore it in the context of our organizational processes.

In short, we try to steer X to be “responsibly irresponsible” as we develop new products. We couple radical, 10x thinking that throws previous conventions to the wind with the discipline to identify risks early, learn cheaply and quickly what’s wrong with our ideas, and face brutal honesty about where we’re succeeding and where we’re not. We now have a system that fuels our optimism while grounding us — just enough — in reality.

Finding people who fall in love with problems

At X, we love new technologies. But technology is the tool, not the end game. If we catch ourselves spending a lot of time refining a new technology and saying, “This could be great for lots of things…someday” without an idea of how to make it so, that’s usually a bad sign. Instead, we want to fall in love with a problem, and aim to understand it so deeply that it becomes easier to find fresh new approaches.

We seek people who are “T-shaped”: they have enormous intellectual flexibility with deep expertise in a particular field, and they can also collaborate easily across diverse domains. (Here’s more about our T-shaped team.) These are the kinds of people who love problems and joyfully apply techniques from one arena to another, like bringing the science of Doritos bags, condoms, and sausage casing to preventing Loon balloons from leaking.

While each moonshot has a core team, we try to keep that team as small as possible, and supplement them with people from a permanent roster of in-house experts, many of whom specialize in helping moonshots make contact with the real world so they can learn as quickly as possible what physics and public opinion have to teach them. This includes things like mechanical engineering, user experience research and design, and public policy. We have a Design Kitchen and several hardware labs that teams can tap for design sprints, rapid prototyping, and failure analysis. These centralized resources make it easy for us to shift people around and quickly help teams of five act like teams of fifty. This also helps us pass along hard-won wisdom and factory lore, while giving us maximum flexibility for when projects fail or go into a reset-and-rebuild mode.

The Design Kitchen at X

Thinking about X as a portfolio

Being a “corporate lab” is a difficult balancing act: place big bets on the future, but don’t spook the people giving you the money. As an Other Bet (one of the Alphabet divisions that’s not Google), we want to be good stewards of the resources invested here and deliver a good return so that we’re trusted to keep the factory open for years to come.

We look for opportunities to balance X’s overall portfolio sensibly, and aim for diversity: a mix of hardware and software, a mix of industries and problems, a mix of ideas that will take more (closer to 10 years) or less (closer to 5 years) time to have an impact. We have clear budgets and limitations; we can aspire to creating significant growth for Alphabet without significantly growing ourselves.

People often ask us how many projects live at X, and the answer is that it moves around and depends on how you count. We have hundreds of ideas that last for a few hours, dozens for a few weeks, handfuls for months. That’s the nature of moonshot-taking: we weed out ideas as we learn more about the size of their potential or their risk. So the number of explorations under our roof will vary at any given time.

Moving through the factory

We now have a clear process for how ideas move through the factory. They start with our Rapid Evaluation (aka “Rapid Eval”) team, where we investigate the seedlings of technology and science breakthroughs that might offer the core ingredients and inspiration for a moonshot.

There are two stages of Rapid Eval investigations. In the first stage, investigators get a few weeks and a few thousand dollars to try to understand a nascent moonshot’s biggest risks; this kills many dozens of ideas quickly. The second stage is “Extended Investigations.” A couple of team members are given a few months and a bit more money to build prototypes, running at the hardest and riskiest parts of the technology to deeply understand the problem they’re trying to solve. As they build their technology prototypes, they must also build a solid techno-economic analysis that proves this idea could survive in the real world as a large business with a real market and real applications. By design, only a handful of ideas survive this process.

Then — and this is a new stage developed in the summer of 2015 and led by Obi Felten — we have the X Foundry. We developed Foundry because an idea that’s only a few months old may still carry a lot of risk, including risks that we don’t fully understand yet. So we wanted to create a special environment that lasts about a year or so where we could keep teams small and nimble (usually with less than 10 people, and often fewer than five) and focused on the riskiest elements. In this stage we want to learn that an idea can eventually be turned into a product and business, or that it can’t. We look to develop confidence that it can exist comfortably in the real world — not in a rosy vision of how the world should be, but in a reality-tested plan that can make money in a reasonable amount of time.

We expect Foundry to have a handful of projects at any one time. We generally expect that half of the projects will be killed, and half will survive. We might send some back to the Rapid Eval team for re-imagining. And if we decide a product has the potential to become a large business soon, we hire a general manager and set it up as an fully-fledged X project like Project Wing and Project Loon are today.

Actively killing our ideas

One of our most valuable cultural habits is our willingness to kill our ideas. We’ve always conditioned Xers to run at their hardest problems and biggest risks first, and as I wrote earlier this year, we’ve developed a number of techniques for making people feel psychologically safe even as they declare that something’s not working and they want to walk away. This ensures we don’t end up with a roster of wasteful projects, and we quickly can move on to new ideas that are more likely to turn into successful moonshot businesses.

Our teams start each day assuming failure is the norm, and we manage moonshots-in-progress on that basis. For example, we don’t just hand out more resources when teams show us that they’re doing well. It’s very easy to work on simple stuff and show some progress, but that doesn’t teach you the hard things that you need to understand deeply to solve the problem in the long run. So we ask teams at X to identify their biggest risks, and we make those into the team’s milestones; knocking down a major risk will unlock more budget or permission to grow the team a little. For example, an early milestone for the Loon team, which is developing balloon-powered Internet, was to have balloons that could last for three months. They’ve achieved that, so now one of their milestones is to lower the total cost of the balloons.

Kill signals are another one of our important tools. These are metrics that a team agrees on when the project starts, which, if you reach them (or in many cases, fail to reach them in a certain timeframe), indicate that, “We should walk away from this project now.” This makes it easy for teams to remain intellectually honest and make tough decisions when they’re faced with difficult results. A recent investigation we called Foghorn proved the value of having kill signals.

Foghorn had the potential to dramatically cut greenhouse gases from transportation and slow the warming of the planet: we produced carbon-neutral fuel out of plain old seawater. Amazing! But awesome tech has to be possible at a reasonable cost. We stared at the techno-economic analysis we’d developed: we couldn’t see how this technique could produce fuel in the next 5–10 years at a cost that’s competitive with gasoline at the pump. Our optimistic selves started to make excuses: “A breakthrough could be just around the corner!” “Isn’t persistence the key to any great innovation?” But the team’s pragmatism kicked in: they couldn’t deny that they’d hit their kill signals, so they made the decision to shelve their work.

Graduating moonshots from the factory

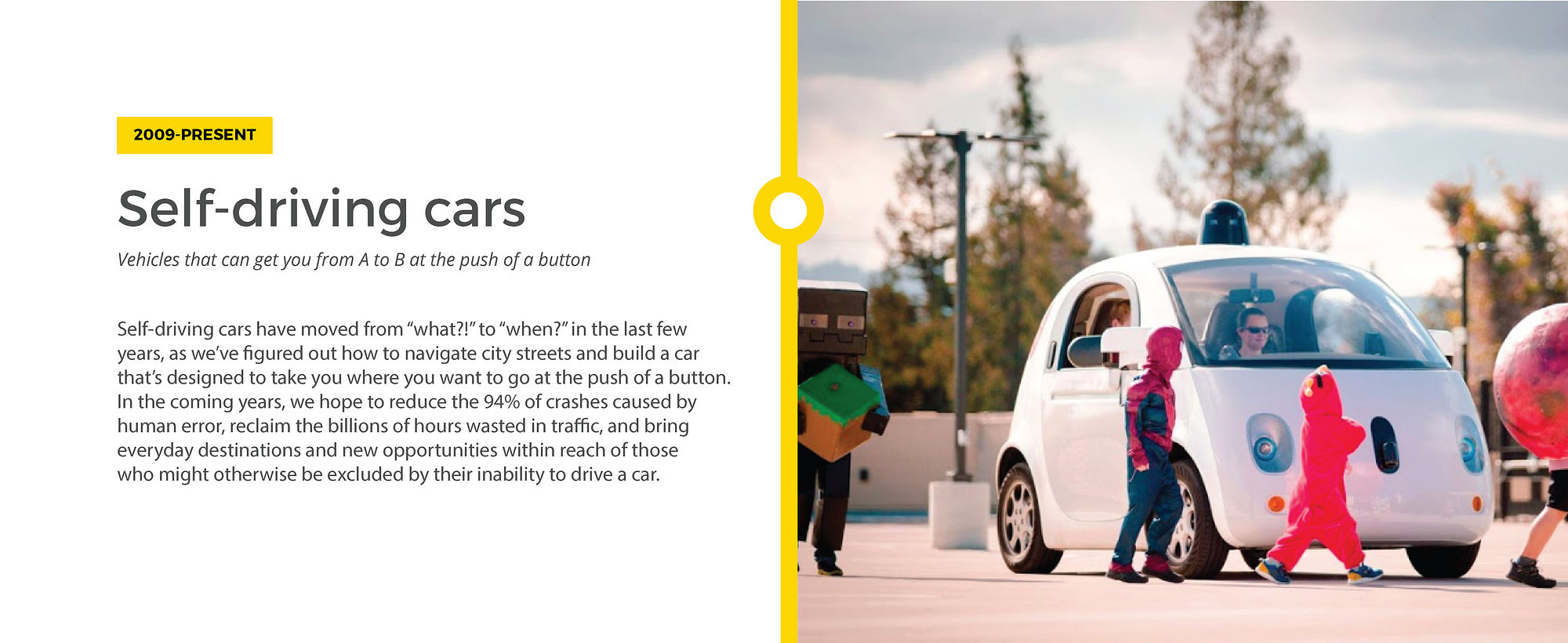

X is designed to be a protected space for long-term thinking, prototyping, and de-risking. Our strength is building the bridge from idea to proven concept. We’ve gotten good at pushing forward things people think are crazy to the point of feasible product prototype. For example, self-driving cars have hit the tipping point of “not if but when,” we licensed our smart contact lens to Novartis, and we moved Google Brain from academic idea to ready for commercial use, and it now powers many Google products.

Once a team is ready to polish products or scale operations, they’re ready to graduate from X. All of our life sciences projects became Alphabet company Verily in 2015. The Genie team, which developed smart software for designing green buildings, blazed a graduation path to the outside world: they’re now the independent venture-funded startup Flux.io. We also graduate early-stage teams as we see that they can bring a lot of value to another part of Alphabet. That’s why Tango, Insight, GCam, Watch, Glass, and Google Brain, among others, graduated to Google. We celebrate these graduations with mortarboards and diplomas, and then put X’s resources back to work on other moonshot ideas. On the whole, our X graduates have had a high survival rate, which means we’re doing a good job of de-risking (and killing) ideas while they’re here.

The world needs more moonshots

We’re by no means done with our factory, but we think it’s working pretty well so far. At six years in, I’m a firm believer that it’s possible to make progress against previously intractable problems by being committed over the long term, and committed to finding answers that are 10x better, not 10% better. I believe it’s possible to manage long-term bets responsibly by creating a culture where people cheerfully run at the hardest things first, kill their work, and head back to the drawing board to find the next great idea. I hope we can continue to get enough right at X that we inspire other people to try for radical new approaches to the problems they care about most. From climate change to transportation, from protecting our oceans and forests to improving access to food and water, there’s no shortage of problems in the world: what we need is more moonshots.